Umhambisi wetshiphu yemagnethi yesixhobo somatshini

| Uphawu | Akho |

| Inombolo yoMzekelo | XYCP |

| Izinto eziphathekayo | Intsimbi yekhabhoni |

| Umbala okhoyo | Mnyama,mhlophe,bomvu,ngwevu,mthubi. |

| MOQ | 1 |

| Inkonzo ye-QEM | Inokwenziwa ngokwezifiso |

| Ukupakisha | Ityala lePlywood |

| Iintlawulo | Imanyano yaseNtshona, igram yeMali, iPaypal,, Ukudluliselwa kocingo. |

| Ukuhambisa ngenqanawe | Ngolwandle.Ngomoya |

| Ixesha lokuzisa | Kwiintsuku zokusebenza ezili-15 emva kwentlawulo yakho. |

| Ubungakanani bobunzima: Isicelo: | Isicelo esingengomGangatho womThengi Umatshini weCNC |

Iimveliso Intshayelelo

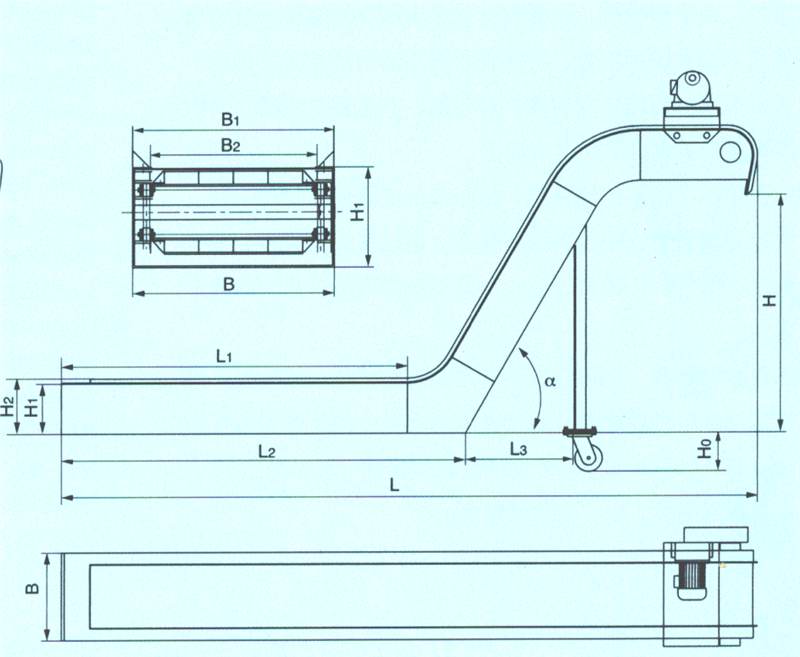

| IiParameters eziphambili zobuGcisa | ||||||

| Ikhowudi | L1 | B | B1 | B2 | H | α |

| Igama | Ukuqokelela ubude | Ububanzi bubonke | Ukuqokelela ububanzi | Ububanzi obusebenzayo | Ukuphakamisa ukuphakama | I-angle yokuphakamisa |

| Ubungakanani |

|

|

|

|

| 0 ~ 60 ° |

| IiParameters eziNcedisayo zobuGcisa | ||||||

| Ikhowudi | H1 | H2 | L | L2 | L3 | P |

| Igama | Ubude beqokobhe | Ubude bubonke | Ubude bubonke | Ukuthe tye ubude | Ukuxhasa umgama womlenze | Amandla emoto |

| Ubungakanani |

|

|

|

|

|

|

Phawula:

(1) Amandla emoto anokumiselwa bububanzi obusebenzayo be-B2, L1 kunye nokuphakama kokuphakama kwe-H.

(2) Ukuba i-pitch yepleyiti yetsheyini yahlukile, ubude be-H1 buya kwahluka ngokunjalo.

I-Pitch 38.1mm Min, ubude be-H1 yi-170mm.

I-Pitch 50.8mm Min.height ye-H1 yi-180mm.

I-Pitch 63.5mm Min ubude be-H1 yi-230mm.

(3) Imilinganiselo iyonke yetanki yamanzi inokwenziwa ngokwembonakalo eyahlukileyo ngokwemfuno yomxumi.

(4) Inokuthi yenziwe kwaye yenziwe ngokweemfuno zomthengi.

Inkcazo

Esi sixhobo sisebenza ngolu hlobo: Ukusebenzisa amandla emagnethi yemagnethi esisigxina ukutsala imathiriyeli yentsimbi, tyibilika kwipaneli yentsimbi engenastainless, ukuze uqokelele kwaye uthuthe intsimbi.Isicoci se-Magnetic chip sifanelekile kwizinto ezilahlwayo, iintsimbi eziqengqelekayo ezingaphantsi kwe-150mm kunye neqela elincinci lentsimbi.

Kukho iindidi ezimbini zemathiriyeli kazibuthe, ferrite kunye neodymium iron boron.Iimpawu zamagnetic zeferrite ziphakathi kwe-600-1000 gauss.Iimpawu zamagnetic ze-neodymium iron boron zinokufikelela kwi-3000 gauss.Isithuba esiphakathi kweemagnethi yi-190.5mm.ngokuba sithetha, kwinkqubo eyomileyo, kukhethwe imathiriyeli ye-ferrite, kwaye inkqubo emanzi, i-iron neodymium izalwe ikhethiwe.

Ukuhanjiswa kwetshiphu yemagnethi isetyenziswa kakhulu ekwenzeni izixhobo zeferromagnetic.I-Magnetic chip conveyor sisixhobo esibalulekileyo sokucoca itshiphu kumatshini wokupholisa amanzi kunye nokupholisa ioli.Isihambisi setshiphu yemagnethi singasetyenziswa kunye nesihluzo sephepha band, sisetyenziselwa ukucocwa kwetshiphu ukwenzela ukubhola imipu.

Indlela yokukhetha

Ngokuqhelekileyo, i-magnetic chip conveyor ingenziwa ngokuhambelana nobukhulu bomthengi, kwaye imodeli inqunywe ngububanzi B2, ebizwa ngokuba yi-XYCP-B2. L/L1 okanye L2, H1,H, kunye nobubanzi B1 okanye B. Ngokuqhelekileyo, i-engile yi-60 °, kodwa kwiimeko ezikhethekileyo, ingaba yi-30 ° okanye i-45 °.

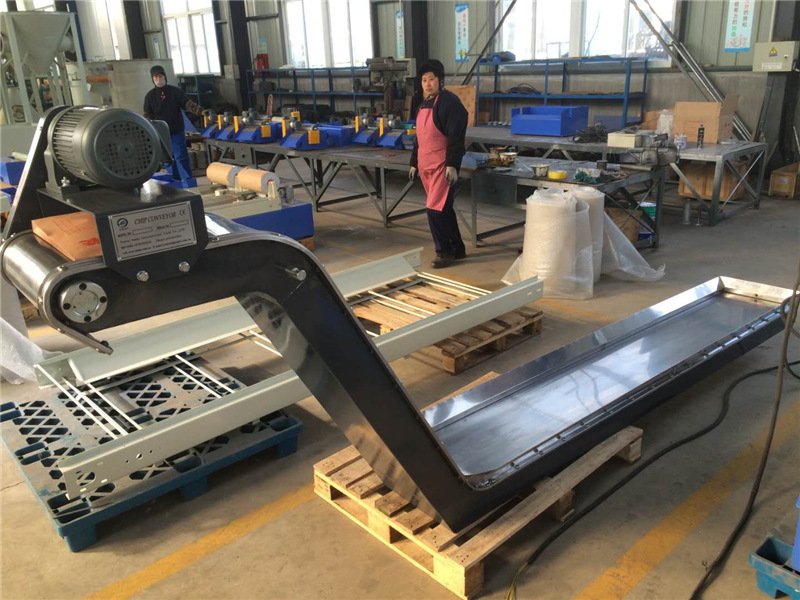

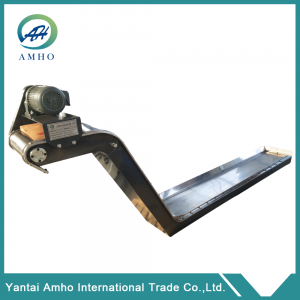

Umboniso wemveliso